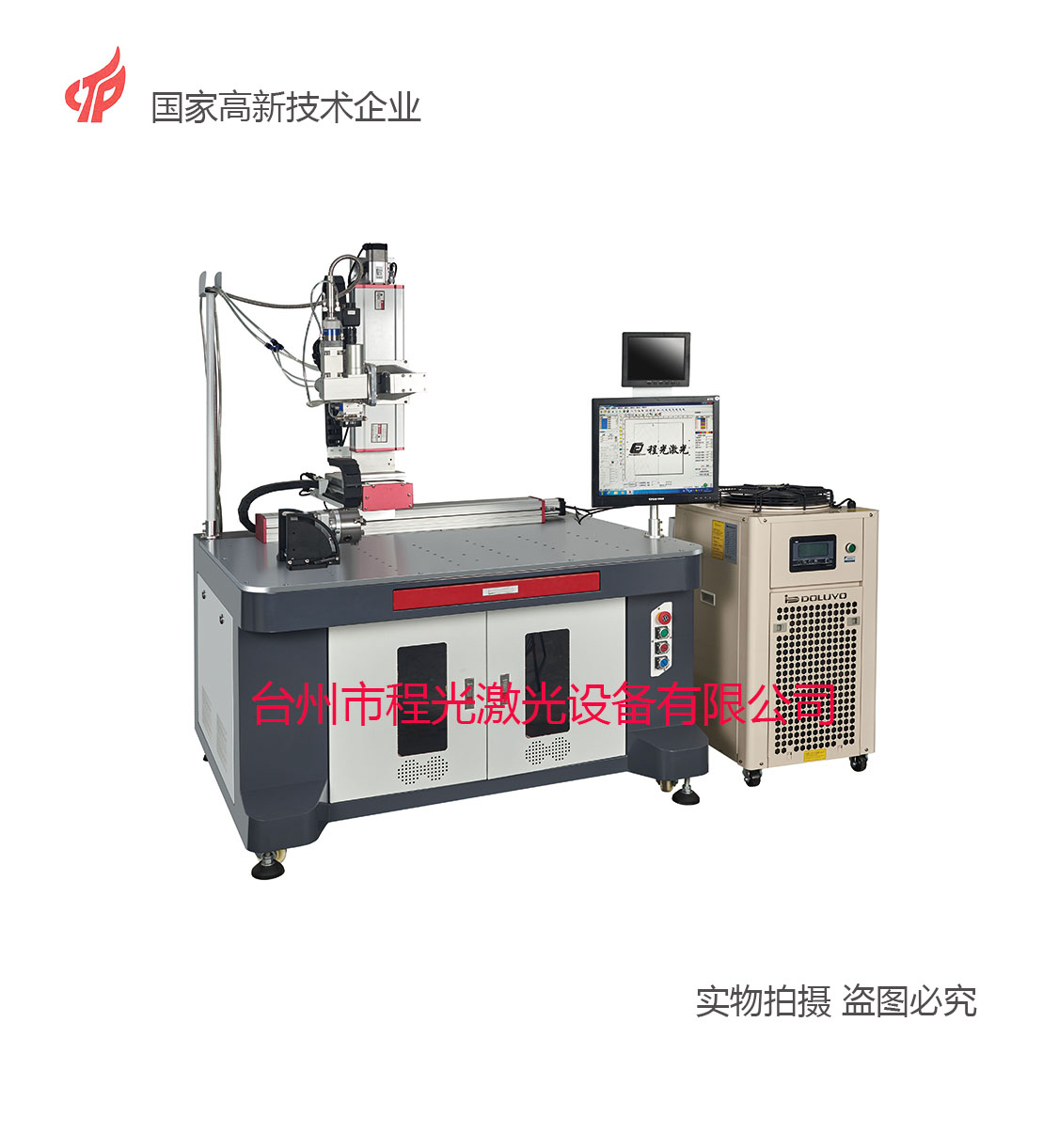

Difference between laser welding machine and traditional welding method

Addtime:2021-04-28 Browse times:909

Laser welding is to make full use of high-energy laser pulse to heat the material in a small area. The energy of laser radiation diffuses into the material through heat transfer, and the material is melted to form a corresponding molten pool. It is a new type of welding method, which is mainly aimed at the laser welding of thin wall materials and high precision parts. It can realize spot welding, butt welding, overlap welding, seal welding, etc. it has high depth width ratio, small welding gap width, small heat affected zone, small deformation, fast laser welding speed, flat welding gap, clean and beautiful. It does not need treatment or simple treatment after welding, The welding gap has high quality, no air hole, can be controlled accurately, the focus light spot is small, the positioning accuracy is high, and the automation technology is easy to realize. It can be said that the emergence of laser welding technology has given the present welding technology a qualitative leap, so that now different materials of metal materials and non-metallic materials can be easily connected.

At the same time, with the continuous upgrading and renovation of the laser welding machine, the precision of the laser welding machine is continuously improved. The refined production and processing mode will make the laser welding technology play an increasingly important role in the future micro processing field.

Although the current price of laser welding machine, laser marking machine and laser cutting machine is more expensive than that of traditional equipment, laser equipment has incomparable competitive advantages in efficiency and technology, It is believed that in the future, laser welding technology, together with other laser application technologies, will inject new power into our current production and processing.